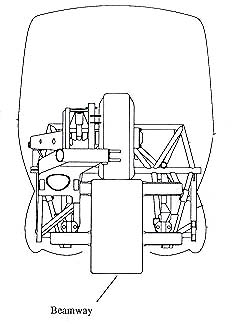

Disney/Bombardier Suspension

The Mark trains use

a slightly different bogie scheme than the Seattle ALWEG and Hitachi

ALWEG monorails. Where the Seattle and Hitachi trains have independent

bogies that have load wheels that extend into the cars, the Mark

III/V, Mark IV and Mark VI trains have load wheels at the ends

of the cars, which are attached to the substructure. Also, instead

of two tires per axle on the Seattle and Hitachi trains, there

is only one on the Mark III/V, IV and VI trains. These load tires

are 445/65R22.5 Michelin XTE2 46.6" diameter , 17.8"

wide truck tires, the same ones you can see on a dump truck or

cement mixer. The tires are nitrogen-filled to reduce the possibility

of fire. They also have run-flat capability. These tires will

last 100,000 miles in normal operation. Maximum rated speed for

these tires is 65 mph (105 km/h). The load capacity of these tires

are 12,800 pounds (5806 kg) each at maximum inflation. There are

12 load tires per 6 car train and 48 guide tires per 6 car train.

These guide tires are 21.5" in diameter. In addition, there

are two steering wheel tires under each cab car to help steer

the suspension up to 3 degrees in either direction. Steering is

accomplished in the intermediate cars by the relative geometry

of the two adjacent cars. Thus, all 12 load tires are steerable,

and the tires are always tangent to the curve. The main suspension

of the cars above the axles is done with air bags (also called

air springs). The air bags are automatically inflated/deflated

by a leveling valve, which allows varying load conditions. There

are also vertical hydraulic shock absorbers. For further information

on the suspension system, see the Bombardier

Mark VI patent. The Mark trains use

a slightly different bogie scheme than the Seattle ALWEG and Hitachi

ALWEG monorails. Where the Seattle and Hitachi trains have independent

bogies that have load wheels that extend into the cars, the Mark

III/V, Mark IV and Mark VI trains have load wheels at the ends

of the cars, which are attached to the substructure. Also, instead

of two tires per axle on the Seattle and Hitachi trains, there

is only one on the Mark III/V, IV and VI trains. These load tires

are 445/65R22.5 Michelin XTE2 46.6" diameter , 17.8"

wide truck tires, the same ones you can see on a dump truck or

cement mixer. The tires are nitrogen-filled to reduce the possibility

of fire. They also have run-flat capability. These tires will

last 100,000 miles in normal operation. Maximum rated speed for

these tires is 65 mph (105 km/h). The load capacity of these tires

are 12,800 pounds (5806 kg) each at maximum inflation. There are

12 load tires per 6 car train and 48 guide tires per 6 car train.

These guide tires are 21.5" in diameter. In addition, there

are two steering wheel tires under each cab car to help steer

the suspension up to 3 degrees in either direction. Steering is

accomplished in the intermediate cars by the relative geometry

of the two adjacent cars. Thus, all 12 load tires are steerable,

and the tires are always tangent to the curve. The main suspension

of the cars above the axles is done with air bags (also called

air springs). The air bags are automatically inflated/deflated

by a leveling valve, which allows varying load conditions. There

are also vertical hydraulic shock absorbers. For further information

on the suspension system, see the Bombardier

Mark VI patent.

|